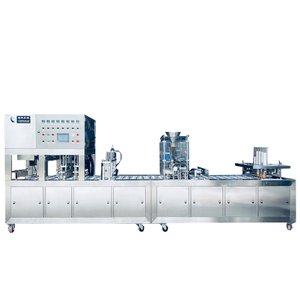

Ice Cubes Cup Filling & Sealing Machine is a packaging machine designed to automatically fill pre-formed cups with ice cubes (or crushed ice) and then seal the cup with a film or foil lid — producing hygienic, ready-to-sell ice cups for drinks, retail, catering, or convenience stores.

Below is a complete, practical guide to how it works, key features, configuration options, and how to choose the right one for your production.

What It Does

This machine automatically:

Denests empty cups

Fills ice cubes into cups

Applies and heat-seals a protective lid (film/foil)

Prints production data (date/batch)

Discharges sealed ice cups to the outfeed conveyor

It eliminates manual labor and ensures consistent portioning, hygiene, and packaging quality.

How the Machine Works – Step by Step

1) Cup Loading / Denesting

Empty PP/PET/PS cups are loaded into the machine’s hopper.

A denester places cups one by one onto the conveyor or rotary table.

2) Ice Feeding / Dosing

Ice cubes (or crushed ice) are delivered from an insulated ice hopper or ice conveyor.

Filling methods:

Volumetric cup filler (simple) — gravity or timed gate, based on cup volume.

Multi-head weigher — high accuracy (e.g., 200g per cup).

Ice size:

Whole cubes (e.g., 20–40 mm),

Half or crushed ice (for better packing density).

3) Film / Foil Lid /Plastic Lid Placement

A pre-cut film or foil lid/plastic lid is automatically transferred and placed on top of each filled cup.

Can use printed film for branding.

4) Heat Sealing

Temperature-controlled sealing bars seal the film/foil to the cup rim.

Parameters (temp/pressure/time) are adjustable for a tight, leak-proof seal.

5) Coding & Printing

An inkjet or laser coder prints date, batch, and other required info.

6) Outfeed / Discharge

Sealed ice cups are moved to the conveyor for packing into cartons or trays.

Key Features to Look For

✔ Hygienic Design

SUS304/316 stainless steel

Washdown-friendly

Enclosed ice feed to minimize melt and contamination

✔ Adjustable Fill

Recipe control for different cup sizes

Volume control (grams/cup)

✔ Automatic Film Feeding

Film reel with automatic feed & cut

Tension control for consistent sealing

✔ PLC + Touchscreen Control

Program recipes by cup size

Alarm & fault display

✔ Safety

Interlocked guards

Emergency stops

✔ Optional Upgrades

Multi-head weigher (for precise weight)

20–60 cups/min versions depending on lanes

Rotary table for higher throughput

Ice crushing system built in

Automatic lid feeder

Conveyor to cartoner

Typical Performance (Indicative)

| Machine Type | Speed | Notes |

|---|---|---|

| Single-lane linear | 800–1000 cups/hr | Small shops, market testing, low volume |

| 2-lane inline | 1200–1,800 cups/hr | Medium production |

4-lane inline can be customized more lanes | 3,000–3,600 cups/hr | Higher throughput |

(Speeds depend on cup size, ice size, and machine model.)

Common Cup Specifications

Cup diameter: 60–120 mm

Cup height: 70–150 mm

Cup material: PP / PET / PS / PLA

Cup volume: 200 ml – 500 ml (typical)

Handling Ice Melt & Hygiene

Since ice melts:

Use insulated hoppers and chutes

Minimize open air exposure

Add drip trays / collection pans

Drain water away from product zone

Typical Line Configuration

Ice maker → Ice buffer / hopper → Ice conveyor → Cup denester → Ice filling station → Film/foil sealing head → Coding station → Outfeed conveyor → Cartoner / palletizer

Choosing the Right Model

Tell me:

Cup size(s) (diameter & height)

Ice type (whole, half, crushed)

Target speed (cups/hour)

Sealing type (film or pre-cut foil)

Available space & utilities (power/air)

I’ll provide:

A specific machine model recommendation

Technical specs

Footprint/laydown drawing

Estimated price range

If you want, I can also prepare a quotation-ready specification sheet you can send to suppliers. Just share the details above.