| Availability: | |

|---|---|

| Quantity: | |

KIS-900

Chunlai

Chunlai’s KIS-900 Rotary Type Cookie Crumbs Cup Lid Filling Sealing Machine offers a great value with filling speeds from 1500-1800 cups/hour and filling capabilities from 50-300g(different from this can be customized). Rotary machines are a great choice for customers that have limited space or that don't require high production rates. This filling sealing machine is a great option for pilot programs, small businesses, business starters and market testing.

KIS-900 rotary type cup filling sealing machine is suitable for packaging a wide range of liquid, paste, granulated and powdered products into pre-formed containers of various size and shapes.

The machine can be used in a variety of applications for the food industry, such as sour cream, yogurt, cheese, butter, guacamole, salsa, mayonnaise, margarine, hummus, dip, salad dressings, seasoning, soup, chocolate, jelly, honey, jam, ketchup, chili sauce, coffee, dry products, cosmetic cream and more.

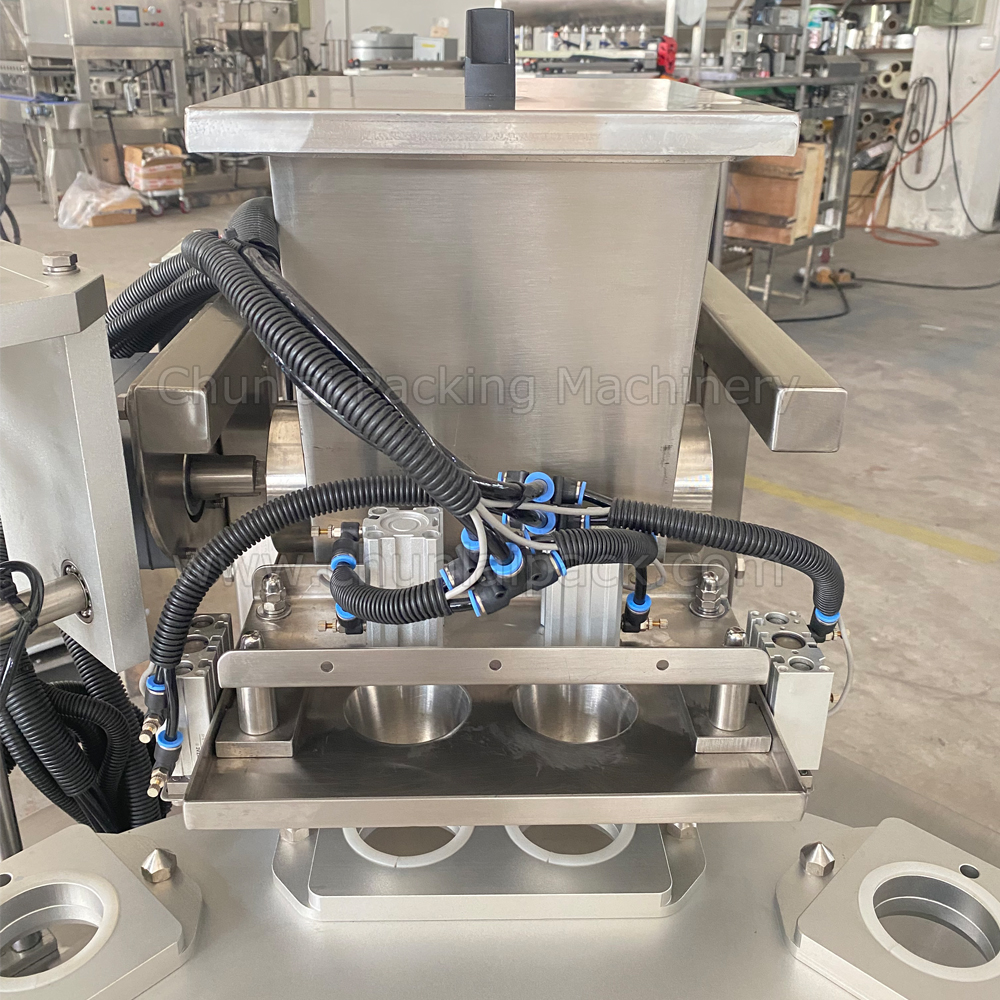

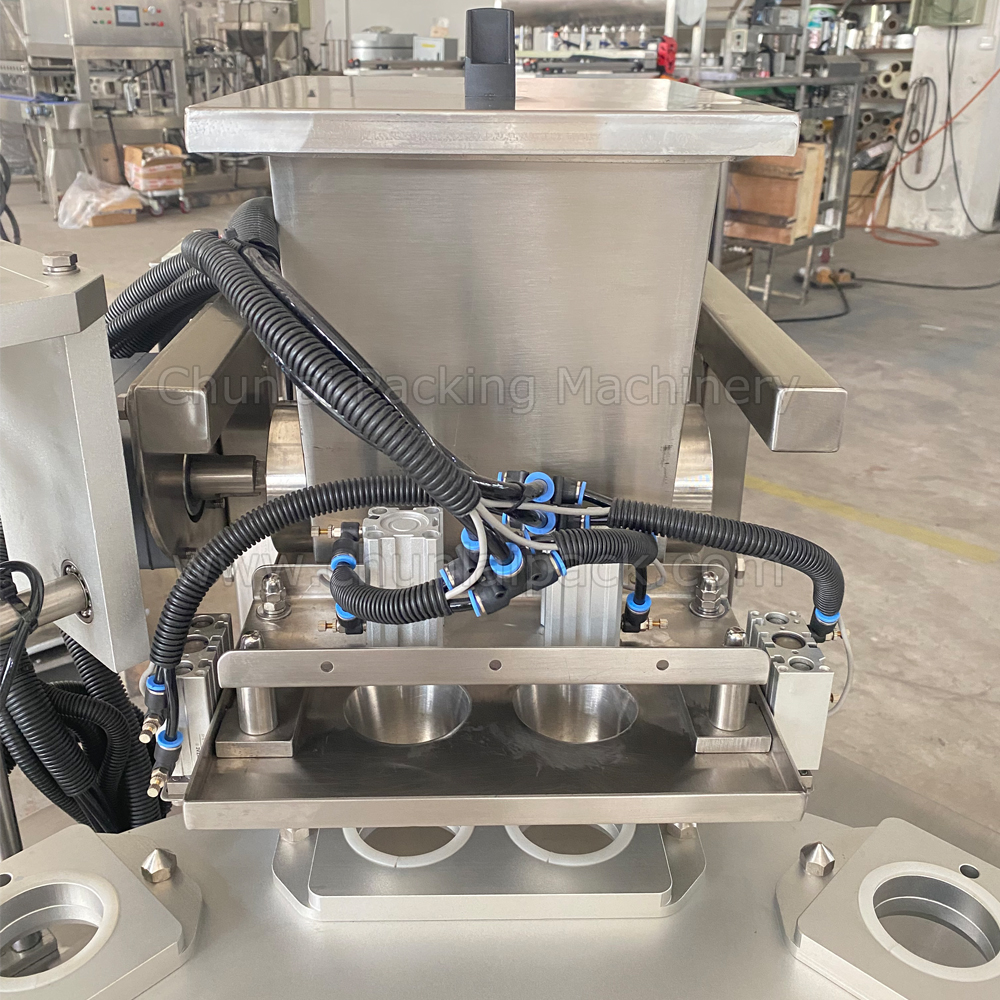

Depending on the output required, the KIS-900 rotary cup filling and sealing machine is designed for one cup or two cups per time. The filling units which can be combined different type fillers on a same machine.

include cup dispenser, filling, heat sealing, automatic ejection

Empty cup dispensing function: it can separate cups accurately, the technology which can avoid the cup damage and deforming.

Filling function: the filling system could be designed based on your product feature.

Liquid: gravity filling, easy for clean

Paste: piston filling, anti-drip, no splash and leakage, the filling system tool free disassemble design.

Granule: measuring cup, weighing for nuts, cereal, cornflakes, popcorn, oats, ect.

Powder: screw

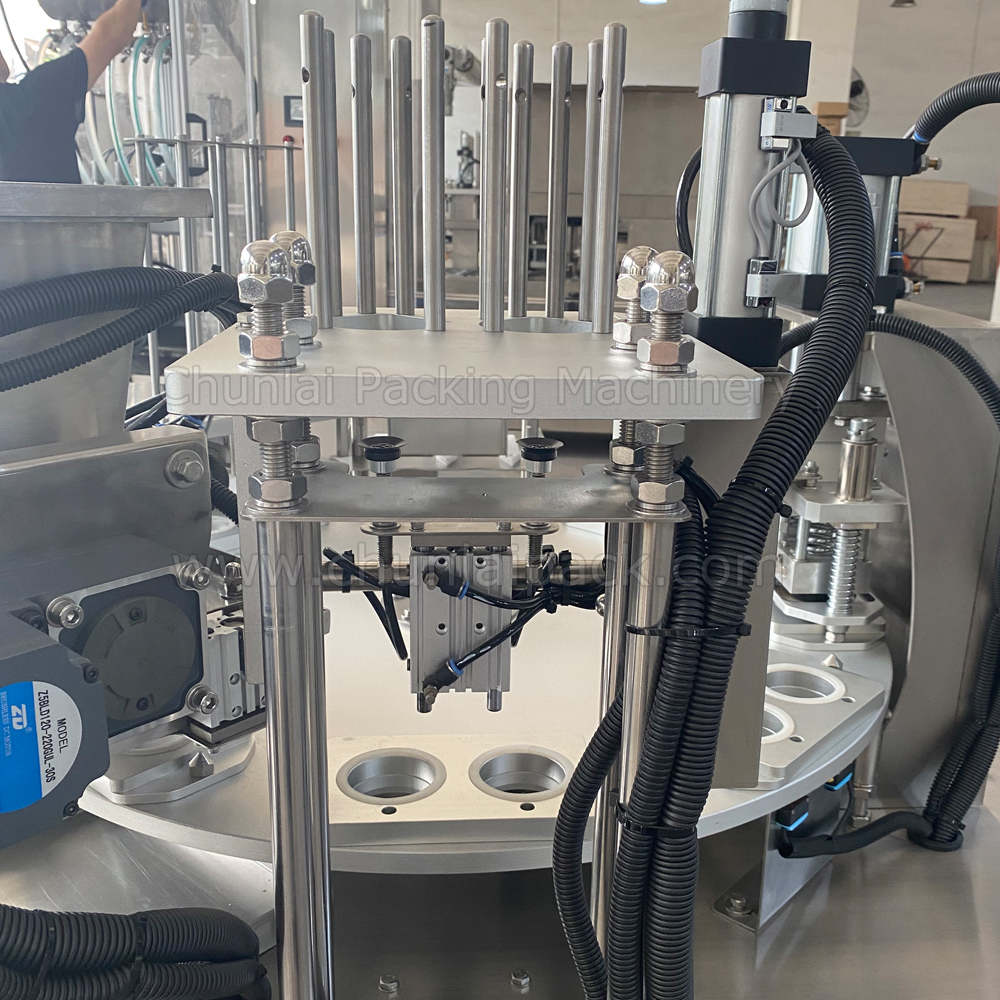

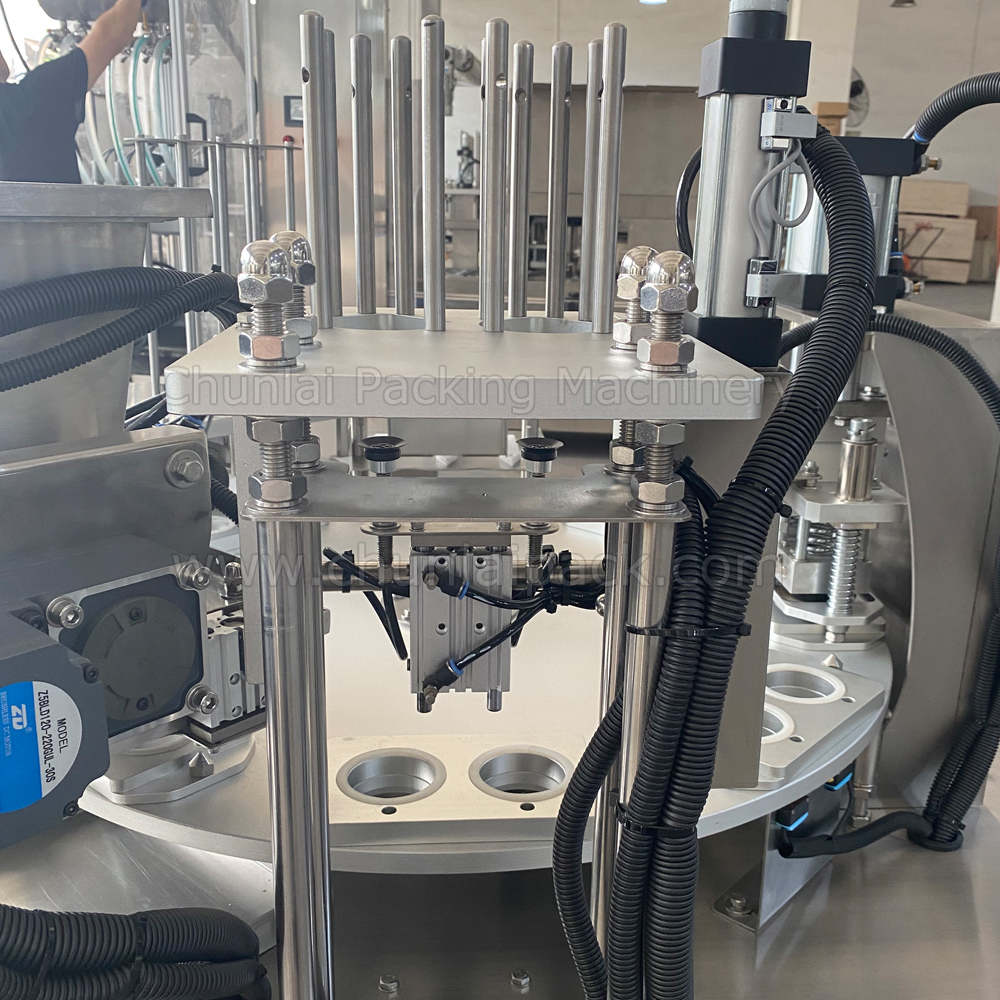

Aluminum foil lids placing function: it make up by 180 rotate vacuum sucker and lids magazine, it can place the lid on the mold fast and accurately.

Sealing function: the sealing temperature can be 0-300 degree adjustment. Independent temperature controller for each sealing head

Automatic ejection system: it made up by cup lifting and pushing system, fast and stable.

Automation control system: it controlled by Mitsubishi PLC

Pneumatic system: it controlled with AirTac cylinder

Variable speed adjustment via speed controller arrange with inverter

Operation panel: Traditional Switches and Buttons for simple operation

cup drop

measuring cup dosing

foil placing

sealing

cup exit

cup lid

Chunlai’s KIS-900 Rotary Type Cookie Crumbs Cup Lid Filling Sealing Machine offers a great value with filling speeds from 1500-1800 cups/hour and filling capabilities from 50-300g(different from this can be customized). Rotary machines are a great choice for customers that have limited space or that don't require high production rates. This filling sealing machine is a great option for pilot programs, small businesses, business starters and market testing.

KIS-900 rotary type cup filling sealing machine is suitable for packaging a wide range of liquid, paste, granulated and powdered products into pre-formed containers of various size and shapes.

The machine can be used in a variety of applications for the food industry, such as sour cream, yogurt, cheese, butter, guacamole, salsa, mayonnaise, margarine, hummus, dip, salad dressings, seasoning, soup, chocolate, jelly, honey, jam, ketchup, chili sauce, coffee, dry products, cosmetic cream and more.

Depending on the output required, the KIS-900 rotary cup filling and sealing machine is designed for one cup or two cups per time. The filling units which can be combined different type fillers on a same machine.

include cup dispenser, filling, heat sealing, automatic ejection

Empty cup dispensing function: it can separate cups accurately, the technology which can avoid the cup damage and deforming.

Filling function: the filling system could be designed based on your product feature.

Liquid: gravity filling, easy for clean

Paste: piston filling, anti-drip, no splash and leakage, the filling system tool free disassemble design.

Granule: measuring cup, weighing for nuts, cereal, cornflakes, popcorn, oats, ect.

Powder: screw

Aluminum foil lids placing function: it make up by 180 rotate vacuum sucker and lids magazine, it can place the lid on the mold fast and accurately.

Sealing function: the sealing temperature can be 0-300 degree adjustment. Independent temperature controller for each sealing head

Automatic ejection system: it made up by cup lifting and pushing system, fast and stable.

Automation control system: it controlled by Mitsubishi PLC

Pneumatic system: it controlled with AirTac cylinder

Variable speed adjustment via speed controller arrange with inverter

Operation panel: Traditional Switches and Buttons for simple operation

cup drop

measuring cup dosing

foil placing

sealing

cup exit

cup lid

Model | KIS-900 | KIS-900-2 |

Production Capacity | 800-1000 cups/hour | 1600-2000 cups/hour |

Filling Range | 50-300g or customized | |

Power | Single phase 220V, 3 phase 220V 3 phase 380V/400V/415V 50Hz/60Hz | |

Power | 1 Kw | 1.5Kw |

Air consumption | 0.6 mз/min | 0.8 mз/min |

Dimension | 1000mm×1000mm×1650mm | 1150mm×1150mm×1650mm |

Weight | 300Kg | 350Kg |

Model | KIS-900 | KIS-900-2 |

Production Capacity | 800-1000 cups/hour | 1600-2000 cups/hour |

Filling Range | 50-300g or customized | |

Power | Single phase 220V, 3 phase 220V 3 phase 380V/400V/415V 50Hz/60Hz | |

Power | 1 Kw | 1.5Kw |

Air consumption | 0.6 mз/min | 0.8 mз/min |

Dimension | 1000mm×1000mm×1650mm | 1150mm×1150mm×1650mm |

Weight | 300Kg | 350Kg |

Machine Frame: Stainless Steel

Bottom Molds: Aluminum Alloy

PLC: Mitsubishi

Cylinder: AirTac

Solenoid valve: Mindmand

Switch: IDEC

Machine Frame: Stainless Steel

Bottom Molds: Aluminum Alloy

PLC: Mitsubishi

Cylinder: AirTac

Solenoid valve: Mindmand

Switch: IDEC

Operation panel: Touch Screen

Servo motor driving

Empty cup dispensing function: according to different cups, some can be designed with vacuum sucker which can guide the cup enter into mold accurately.

Empty cup detecting function: no cup no filling or no cup machine stops

Filling: cup lifting function

Filling tank: mixing, level control, double jacket, CIP washing ball

Roll Film Storage Device

Blank Film Fixer: to calculate the film length of cup for saving the film cost

Eye Mark Auto Correction: Collocating with a photocell sensor of film pattern mark

Color ribbon date printer for roll film

Automatic Capping System: put plastic cap after sealing

Safety protection: it is optional function, it make up by plexi glass plates, aluminium and stainless steel, has safety switches which protect the operator.

Laminar flow-HEPA filter unit

Out-feed conveyor

Modified Atmosphere Packaging (MAP)

Operation panel: Touch Screen

Servo motor driving

Empty cup dispensing function: according to different cups, some can be designed with vacuum sucker which can guide the cup enter into mold accurately.

Empty cup detecting function: no cup no filling or no cup machine stops

Filling: cup lifting function

Filling tank: mixing, level control, double jacket, CIP washing ball

Roll Film Storage Device

Blank Film Fixer: to calculate the film length of cup for saving the film cost

Eye Mark Auto Correction: Collocating with a photocell sensor of film pattern mark

Color ribbon date printer for roll film

Automatic Capping System: put plastic cap after sealing

Safety protection: it is optional function, it make up by plexi glass plates, aluminium and stainless steel, has safety switches which protect the operator.

Laminar flow-HEPA filter unit

Out-feed conveyor

Modified Atmosphere Packaging (MAP)

popcorn

cereal & corn flakes

popcorn

cereal & corn flakes