Here's how it works for your application:

Machine Functions

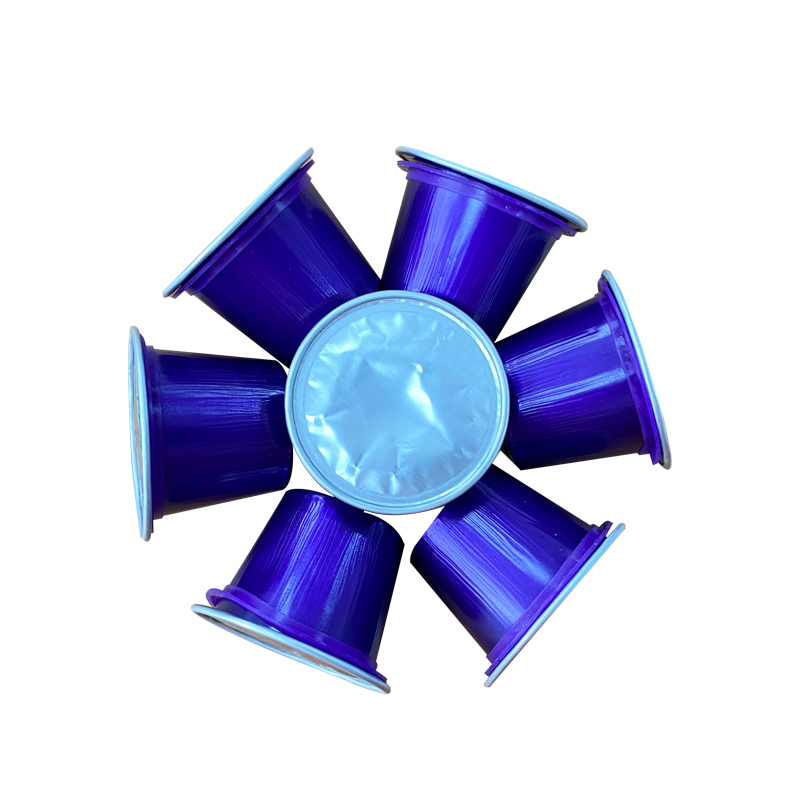

Cup Denesting

Automatically drops empty cups into the rotary turntable. Or manually put cups, it's according to different types cups

Cups can be two-compartment (biscuits + chocolate) or single-compartment with partition.

Filling System

Chocolate Dipping Sauce: Uses a heated hopper with piston or servo pump filling (keeps chocolate warm, fluid, and accurate).

Finger Biscuits: Vibratory feeder or counting system drops the correct number of sticks into the biscuit side. Or manually put biscuit

Film Placement & Sealing

Heat-sealing with aluminum foil / laminated film lid.

Ensures airtight, hygienic sealing to keep biscuits crispy and chocolate fresh.

Optional Functions

Nitrogen flushing (extends shelf life).

Coding/printing (date, batch number).

Secondary lid or snap-cap placing.

Sleeve labeling or shrink wrapping.

Advantages

Compact design (rotary indexing table saves space).

Accurate dosing of chocolate and biscuit sticks.

Flexible: can handle 2-compartment or multi-compartment cups.

High hygiene (food-grade stainless steel, easy cleaning).

Customizable for different cup shapes and sizes.

Typical Output

8,00–1,800 cups/hour depending on cup size, compartments, and number of working stations.

✅ In short: A rotary cup filling sealing machine with dual-filling system (chocolate + biscuits) is the standard choice for finger biscuit chocolate dipping snack packs.

Would you like me to also suggest a packaging layout design (like what kind of cups, lids, and presentation boost sales for this product)?